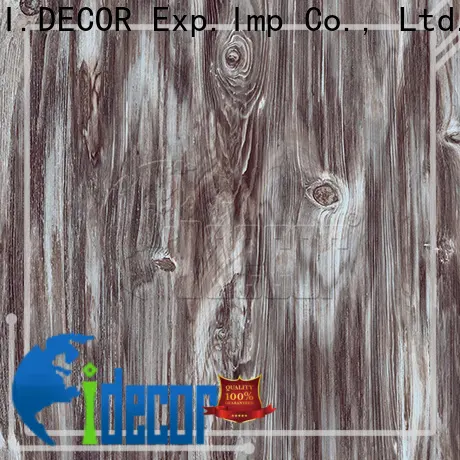

stable wood design paper customized for master room

Place of origin:

China

Price Terms:

FOB, CIF

Minimum Order:

5000m per size per color. Less than this quantity please contact us.

Package:

Plastic film inside, kraft paper outside. Any customized package can be discuss.

Payment Terms:

L/C, D/P, T/T

wood design paper

description

This product is safe enough. The dyes of fabrics are treated to contain no harmful chemicals that would cause any skin irritants. With excellent scratch resistance and anti-dirty, it is ideal for home decoration

wood design paper

SPECIFICATIONS

| Place of origin | China |

|---|---|

| Price Terms | FOB, CIF |

| Minimum Order | 5000m per size per color. Less than this quantity please contact us. |

| Package | Plastic film inside, kraft paper outside. Any customized package can be discuss. |

| Payment Terms | L/C, D/P, T/T |

The product is widely used on the flat surface. The product can be cut into any shapes and sizes. This product is great for covering any sizes of furniture.

Suggested Videos

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

QUICK LINKS

SPANISH FLYING HORSE

Contact Us

China Office Address: No. 10 Xile Street, Leping Town, Sanshui District, Foshan City 528137

India Office Address: Shinto Corp, B7 Hind Saurashtra Industrial Estate, MV Road, Marol, Andheri East, Mumbai 400 059 Maharashtra India

Malaysia Office Address: 12038, Jalan Cendrawasih 2,Bandar Putra,Kulai,Johor,Malaysia 81000

Bangkok Office Address: 82-86 Soi Charoen Nakhon 50, Samre, Thonburi, Bangkok 10600